Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

KODI Closed Loop Spray Dryer With Solvent Recovery

1, Closed Loop Spray Dryer / Closed Cycle Spray Dryer

2, Through Inert Gas (Nitrogen)

3, Easy operation and control

KODI Closed Loop Spray Dryer With Solvent Recovery Description

The closed-loop spray dryer is suitable for the drying operation of solutions, emulsions, suspensions containing organic solvents,volatile toxic and harmful gases, and solvent recovery from material liquids. Meanwhile, due to the strict control of oxygen content during the drying process, this spray dryer can also be used to dry materials that are easy to decompose and oxidize.This drying system not only inherits all the advantages of the spray dryer, but also does not have any powder leaking out of the body during the drying operation, so the yield of finished products can almost reach 100%. The solvents recovered through the recovery system can be recycled after processing, which greatly reduces the production cost.

Details of KODI Closed Loop Spray Dryer With Solvent Recovery

KODI Closed Loop Spray Dryer With Solvent Recovery Features

(1) The system process design of the equipment is explosion-proof type. Explosion venting disc or directional explosion venting devices are installed on the main body and key parts of the equipment. This ensures the safety of equipment operation (for systems with volatile toxic and harmful gases, a recovery pipeline can be designed after the explosion venting device).

(2) The system is equipped with a condensation system and a recovery system for drying the solvent in the liquid, allowing the solvent in the liquid to be recovered and reused after secondary treatment, greatly reducing production costs.

(3) The equipment is designed to be fully enclosed, so the yield of dried products during the drying process is very high, which cannot be achieved by other types of dryers.

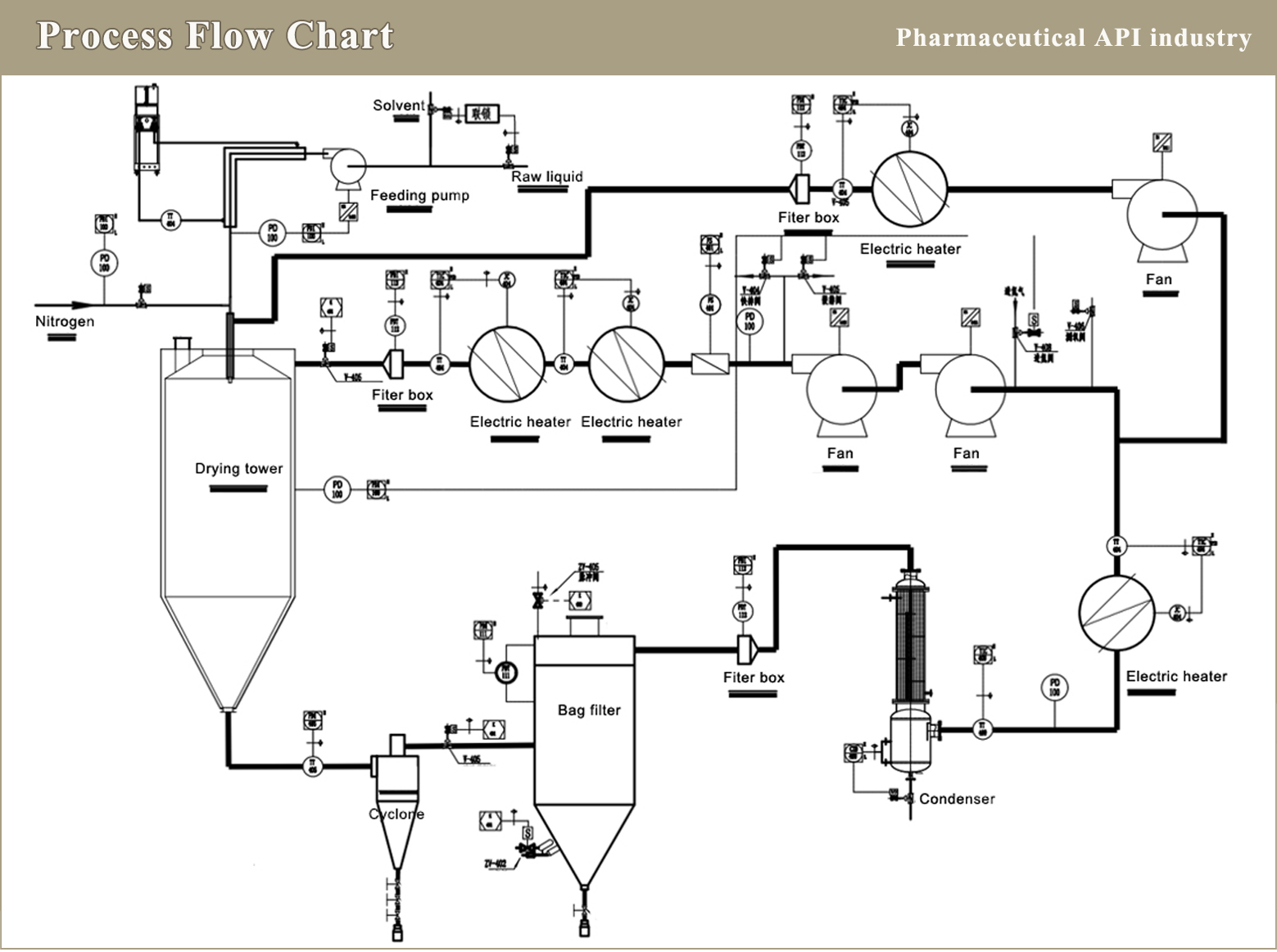

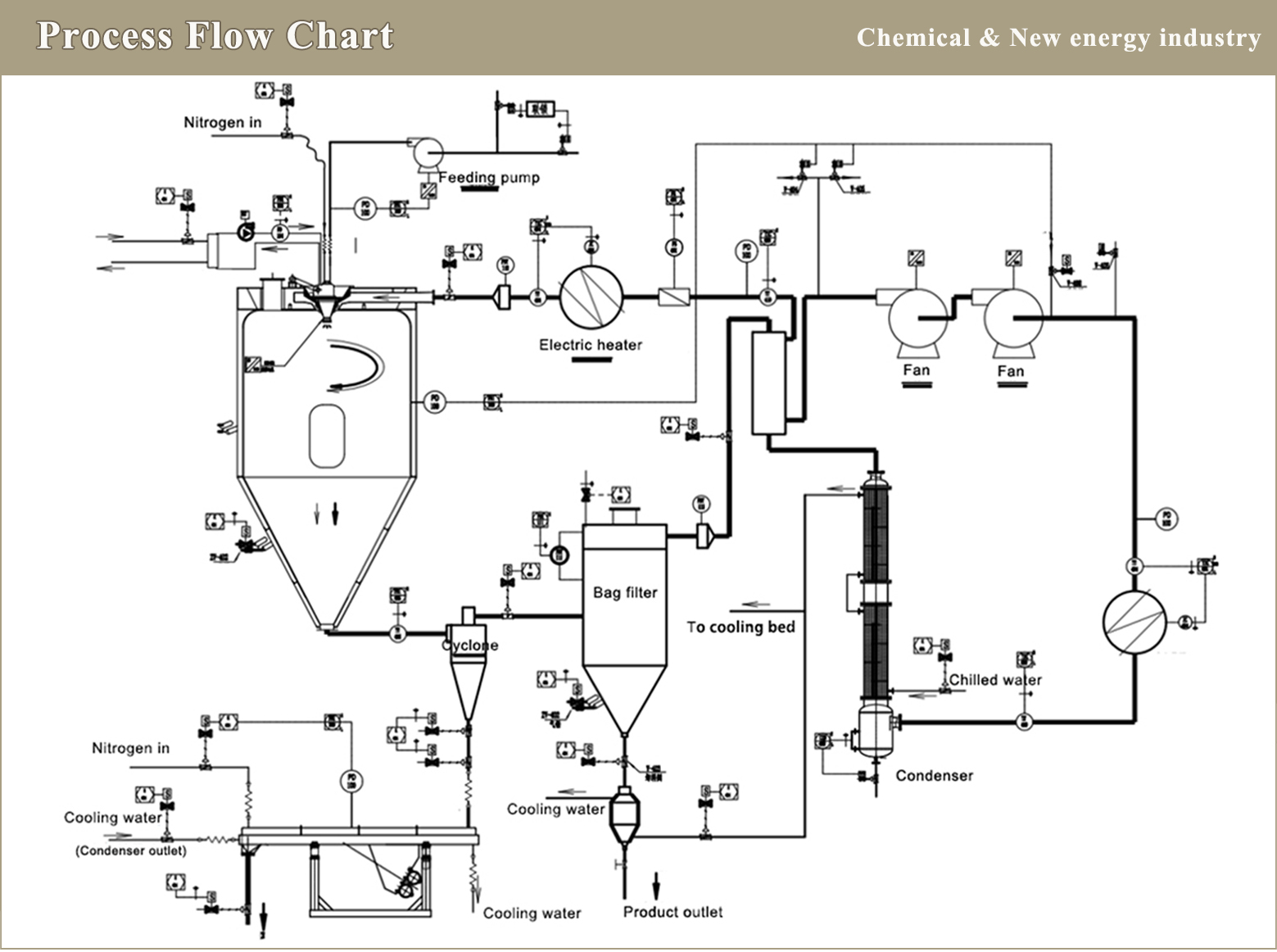

KODI Closed Loop Spray Dryer With Solvent Recovery Working Principle

Firstly, heated inert gas (usually nitrogen) is filled into the drying tower, and the raw liquid material is transported to the

centrifugal atomizer or nozzle through a feeding pump. The liquid material is sprayed into small droplets, which undergo

sufficient heat exchange with hot nitrogen in the drying tower. The liquid part of the material evaporates instantly, and the

solid part forms a powdery material that settles at the bottom of the tower. Finally, the dried powdery material is discharged through a gas-solid separation device.

Among them, the evaporated organic solvent gas is subjected to dust removal treatment by devices such as cyclone separator and bag filter under the action of the fan, and then the saturated organic solvent gas after dust removal is condensed into liquid and discharged from the condenser. To prevent the liquid from being carried out, a gas-liquid separator is added later. During this process, the inert gas used as a drying medium is continuously heated and reused as a drying carrier within the system.

Working Successful Experience by KODI Closed-loop Spray Dryer