Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

Description of Three-dimensional Moving Mixer

The mixing barrel moves in multi-directions. Materials have no centrifugal force effect, specific gravity segregation, lamination and accumulation during mixing. Mixing rate can reach over 99%. So far, this machine is one ideal mixer among all kinds of mixers. The loading capacity of barrel is good. It can reach 80%(40&%for normal ones).

Each part of drum is transited by circle arc and polished precisely, meeting the GMP requirements.This machine is used high homogeneity mixing of powdery and particle materials in such trades as pharmaceutical, food, chemical, light industry, machinery, electronics, mining and metallurgy, national defense industry and scientific research etc.

Application of Three-dimensional Moving Mixer

Three-dimensional moving mixer is mainly used for high homogeneity mixing of powdery and particle materials in areas such as pharmaceutical, food, chemical, light industry, machinery, electronics, mining and metallurgy, national defense industry and scientific research etc.

Features of Three-dimensional Moving Mixer

1. Materials have no centrifugal force effect, specific gravity segregation, lamination and accumulation during mixing. Each component can be mixer under wide gap of wet proportion, mixing rate reaching above 99.9%.

2. Loading coefficient can be 80% ( 40% for normal ones).

3. The structure is compact, and the transmission adopts stepless speed regulation (Inverter regulation or electromagnetic speed regulation). It is very convenient to operate.

4. The mixing tank adopts arc transition and is polished well. It meets the requirements of GMP.

Working Principle of Three-dimensional Moving Mixer

The loading barrel performs a composite motion including horizontal moving, rotation and turning when driven by the main drive shaft. In the space, by which, materials also performs 3-dimensional motion inside the barrel so that all kinds of materials inside the barrel flow, diffuse, penetrate each other and finally form uniform states. It avoids the specific gravity segregation, lamination and accumulation during mixing because of the centrifugal force.

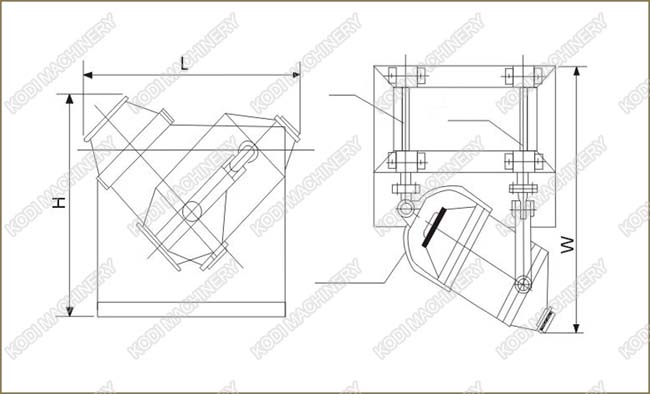

Drawing of SYH Moving Mixer

Customers Project Site of KODI Moving Mixer

Packing and Delivery of KODI SYH Moving Mixer

Technical Parameters of Three-dimensional Moving Mixer

|

model |

SYH-1 |

SYH-5 |

SYH-15 |

SYH -50 |

SYH -100 |

SYH -200 |

SYH -400 |

SYH -600 |

SYH -800 |

SYH -1000 |

SYH -1500 |

|

barrel volume(L) |

1 |

5 |

15 |

50 |

100 |

200 |

400 |

600 |

800 |

1000 |

1500 |

|

Max. loading volume(L) |

0.9 |

4.5 |

13.5 |

45 |

90 |

180 |

360 |

540 |

600 |

750 |

1200 |

|

Max. loading weight (kg) |

0.5-0.9 |

2.4-4.5 |

7.4-13.5 |

25-45 |

50-90 |

100-180 |

200-360 |

300-540 |

400 |

500 |

750 |

|

speed of driving shaft |

30 |

25 |

25 |

25 |

20 |

20 |

15 |

15 |

10 |

10 |

10 |

|

powe of motor (kw) |

0.12 |

0.25 |

0.37 |

1.1 |

1.5 |

2.2 |

4 |

5.5 |

7.2 |

11 |

11 |

|

size(mm) |

500× |

600× |

800× |

1150×

1400 |

1250×

1800 |

1450×

2000 |

1650×

2200 |

1850×

2500 |

1900×

2400 |

1950×

2500 |

2600×

2500 |

|

weight(kg) |

50 |

50 |

200 |

300 |

800 |

800 |

1200 |

1200 |

1650 |

1800 |

2500 |