Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

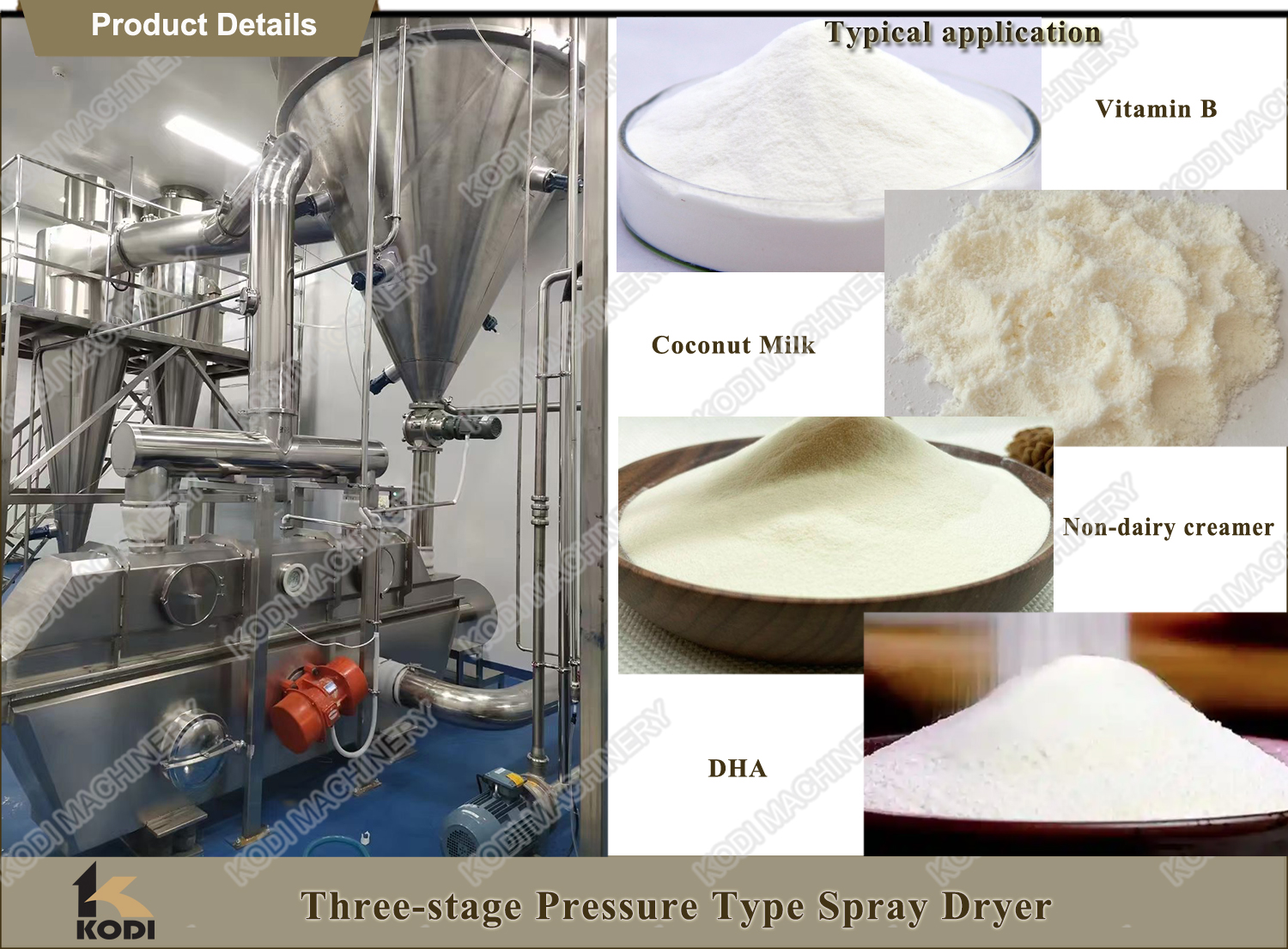

KODI New Design Three-stage Pressure Type Spray Dryer

1, Three stage pressure spray dryer / pressure nozzle spray dryer

2, Liquid or slurry drying processor

3, Easy operation and control

4, Stainless steel

Three-stage Pressure Spray Dryer Description

This system is a special spray drying system, which adopts the form of three-stage drying. The first stage uses a pressure spray drying system to dry the materials into solid materials and remove a large amount of moisture. The second stage is a built-in fluidized bed drying system, through which the materials are further dried. Finally, a vibrating fluidized bed drying cooler is used to further adjust the final moisture of the materials and cool the materials to meet the requirements that the materials can be packaged immediately after discharging.

Three stage Pressure Spray Dryer Application

It could be used for vitamin B3, vitamin B5, non-dairy powder, coconut milk powder, walnut milk, DHA, Production of donkey milk powder, mare's milk whey protein, etc.

Three stage Pressure Nozzle Spray Dryer Advantages

The advantages of the pressure type upper exhaust spray drying tower over the lower exhaust pressure tower are:

1. Energy consumption advantage: The upper exhaust tower only consumes about 2.5kg of steam to evaporate 1kg of water, which can save 8-10% of steam;

2. Save construction investment: For equipment of the same specifications, the height of the upper exhaust tower is reduced by 7-10m compared to the lower exhaust tower;

3. Good product quality: The particles of the new tower powder are uniform, with fewer larger and smaller particles. Good color, particle size, and blending properties;

4. Easy to clean: The tower structure is simple and easy to manufacture. Due to the direct connection between the column and cone of the tower, there are no dead corners during cleaning. After opening the tower door, it is easy to clean every part that comes into contact with dust;

5. Reduce emissions and save energy to reduce labor intensity: The tower can be cleaned every few days during continuous production, which reduces emissions, saves energy, and reduces labor intensity for workers;

6. Automation control system: using PLC and touch screen control system, key parameters can be controlled and displayed. DCS configuration can be carried out with your company, or our company can independently complete the configuration in the spray drying system.

Pressure Nozzle Spray Dryer Technical Parameters

|

Model Item |

YNPG-25 |

YNPG-50 |

YNPG-100 |

YNPG-150 |

YNPG-200 |

YNPG-300 |

YNPG-500 |

YNPG-1000-2000 |

|

|

Evaporated Capacity (kg/h) |

25 |

50 |

100 |

150 |

200 |

300 |

500 |

The index depends on the practical situation. |

|

|

Diaphragm Pump |

Power(KW) |

0.35 |

4 |

7.5 |

11 |

15 |

22 |

30 |

|

|

Pressure |

It can be adjusted from 0.6 to 5 according to the material experient. In general, the pressure will be between 1 and 3. |

||||||||

|

Heating Style |

electricity |

electricity +steam |

electricity +coal fuel (oil) hot air furnace |

||||||

|

Diameter Of Tower Body (mm) |

1300 |

1800 |

2400 |

2600 |

2800 |

3200 |

3800 |

||

|

Total Height Of Equipment (mm) |

7800 |

9200 |

11600 |

14000 |

15300 |

17100 |

19000 |

||

YPG pressure nozzle spray dryer has a very mature technology and process, and KODI company has rich installation experience and good after sale service .