Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

Characteristics of Multi-functional Stainless Steel Extracting Tank

I. Properties & applications

It is special device applicable for leach the constituent as required for herbal extraction by liquid solvents, which meets the production process requirements of many solvents such as water , ethanol, acetone. It is used for the extraction of effective constituent from roots, stems, leaves, flowers, fruits and seeds of plants or brains, bones and organs of animals, or natural minerals. It is widely applied in the industries including TCM, API, foodstuff and beverages.

II. Structural composition:

The unit consists of extraction tank, condenser, cooler, vapor-liquid separator, oil-water separator, filter and circulation pump.

There are various types of extraction tank: positive cone, straight cylinder, inverted cone, mushroom shape, its cylinder body is provided with jacket and insulation layer, its top is feeder nose and foam catcher, its bottom is pneumatic residue discharging door, a filter screen is equipped on the residue discharging door.

III. Technical features:

( 1 ) The residue discharging door, driven by pneumatic force , safety locking type, it is zero leaked ,does not open automatically under sudden power breakdown or gas shutting, to be operated safety and reliably.

( 2 ) The foam catcher, quick-opening, is easy for cleansing and convenient for operation.

( 3 ) Special side discharge structure prevents from the jamming of discharged materials which is easily heated and stewed ,and easily assembled and dis-assembled, or cleansed.

( 4 ) Secondary steam distributor effectively avoid the uneven distribution of steam convenient operation.

( 5 ) Oil-water separator is able to collect light or heavy oil, with intuitive and convenient operation.

( 6 ) There are sectional heating mode and bottom heating mode for jacket, which can be quickly boiled at the beginning stage ,and remain its faint boiling status after boiling up, so as to vaporize fully, and keeps a consistency of temperature in the extraction tank.

( 7 ) Multi-point reasonable layout in online cleaning device enables the cleaning to be more conveniently, quickly and completely.

( 8 ) Able to meet various extraction processes including pressurized extraction ,normal pressure extraction and pressure reduction extraction, and suit the change of the production conditions like high temperature, normal temperature and low temperature.

( 9 ) Arched filter screen, along with long & circular holed filter structure , enlarges its filtration area and enables its screen not to be jammed.

(10) The lifting cylinder of fair-sized residue discharging door is acted with double cylinder, which ensures the safety and stability of operation.

Usage of Multi-functional Extracting Tank

KODI multi-functional extracting tank is suitable for Herbal extraction. foodstuff and chemical industry. It can be applied to following process: normal pressure or high pressure water boiling, warm water soak, heat return, coercive circulation infiltration .aromatic oil extracting and organic solvent recovery etc. Best extracting effect, short extracting time and high content of extracting liquid. The agitator can be screw of blade type. Made by high quality stainless steel can meet the GMP certification needs. It can be used in pharmaceutical, food-stuff, chemical industry etc.

Main Parameters of Stainless Steel Extracting Tank

ZDH Model Extracting Tank

|

Model Parameter |

ZDH-1.0 |

ZDH-2.0 |

ZDH-3.0 |

ZDH-6.0 |

ZDH-8.0 |

ZDH-10.0 |

|

Total volume |

1.2 |

2.3 |

3.3 |

6.5 |

8.6 |

11.0 |

|

Jacket design pressure |

0.30 |

|||||

|

Jacket design temp. |

143 |

|||||

|

Internal design pressure |

NP |

|||||

|

Diameter of feeder mouth |

400 |

400 |

400 |

500 |

500 |

500 |

|

Condensing area |

5.0 |

6.5 |

9.5 |

15.0 |

20.0 |

25.0 |

|

Cooling area |

0.5 |

1.0 |

1.0 |

2.0 |

2.0 |

3.0 |

|

Filtration area |

0.25 |

0.25 |

0.3 |

0.3 |

0.4 |

0.5 |

|

Steam consumption |

235 |

315 |

340 |

665 |

775 |

965 |

|

Weight |

1150 |

1680 |

2500 |

3230 |

4330 |

6550 |

TQB Model Extracting Tank

|

Model Parameter |

TQB-1 |

TQB-2 |

TQB-3 |

TQB-6 |

TQB-8 |

|

Volume |

1200 |

2300 |

3200 |

6300 |

8500 |

|

Design pressure in tank ( Mpa ) |

0.09 |

||||

|

Design pressure in jacket ( Mpa ) |

0.3 |

||||

|

Dimeter of material inlet |

400 |

400 |

400 |

500 |

500 |

|

Heating area |

3 |

4.7 | 6 | 8 | 11 |

|

Condensing area |

5 |

6 |

8 |

15 |

20 |

|

Cooling area |

1 |

1 |

1 |

2 |

2 |

|

Steam consumption |

245 |

325 |

345 |

645 |

0.4 |

|

Water consumption |

5 |

5 |

7 |

10 |

12 |

|

Dimaeter of slagging door |

800 |

800 |

1000 |

1200 |

1200 |

Remark: Dimension is used for reference only.

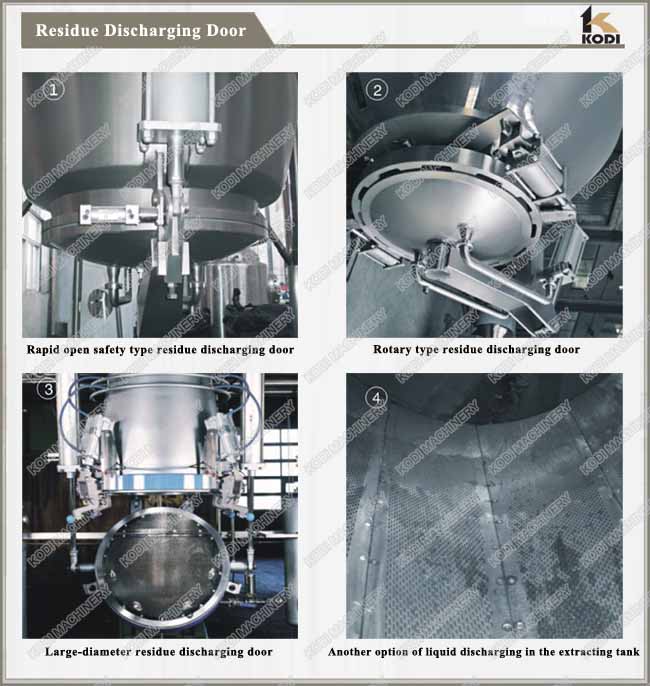

Residue Discharging Door

1 Rapid open safety type residue discharging door

The tank cover can be automatically opened and closed. It adopts three-cylinder control and is provided with safety device to avoid accidental operation and provide high safety factor. It is suitable for use in small and medium-size reside discharging vent.

2 Rotary type residue discharging door

The tank cover can be automatically opened and closed. High temperature and high pressure extraction can be achieved in the swivel type product. It provides more selection for extracting technology. It can also meet some special technological requirements. With good safety guarantee functions and the extracting tank has no leakage.

3 Large-diameter residue discharging door

The tank cover can be automatically opened and closed. High temperature and high pressure extraction can be realized to provide more selection for extracting technology. With high safety factor, the residue discharging door is suitable for residue discharging of large-diameter upside-down type extracting tank.

4 Another option of liquid discharging in the extracting tank

(1) The filter board at the bottom of the extracting tank is made of two layers. The first layer is a 5-6mm thick stainless steel sheet with a thickness of 0.6mm thick is at the top of this supporting layer, and long holes of 0.5*10mm are spread over the stainless steel sheet. The long holes are comparably not easy to be blocked.

(2) According to material requirements of customers ,the filter barrel is installed on the internal bladder or the extracting tank. Vertical grain type filter screen can be adopted. The filtering area of the filter barrel is several times higher than the bottom area, which can solve the problem of blocking and difficult liquid discharging at the bottom of the extracting tank.

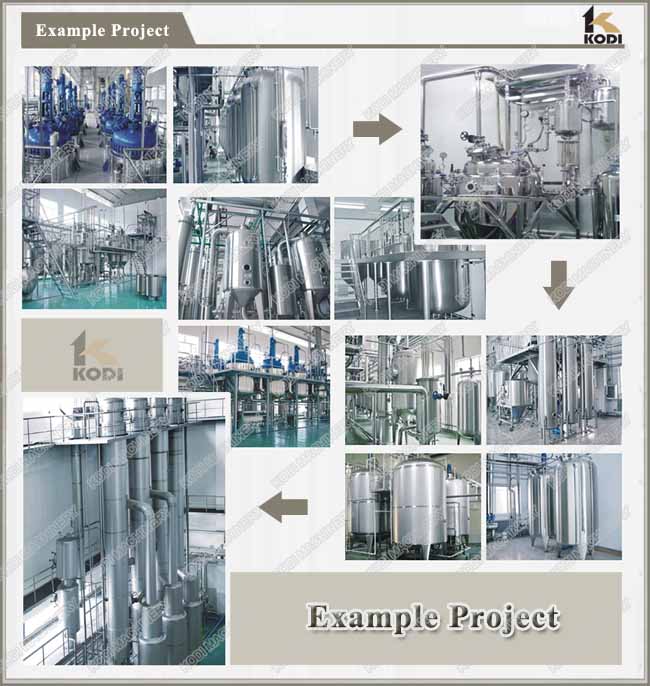

Sucessful Project

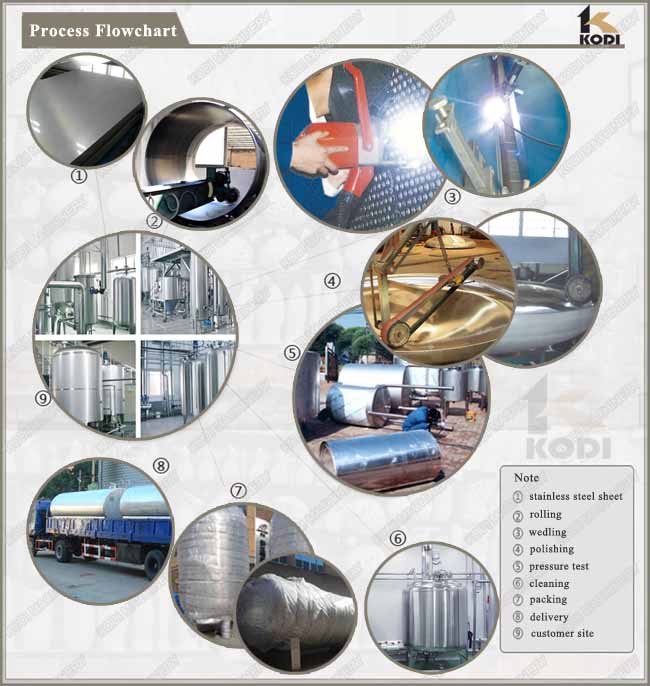

Extracting Tank Process Flow Chart